A Comprehensive Review of Formlab Form 3D Printer

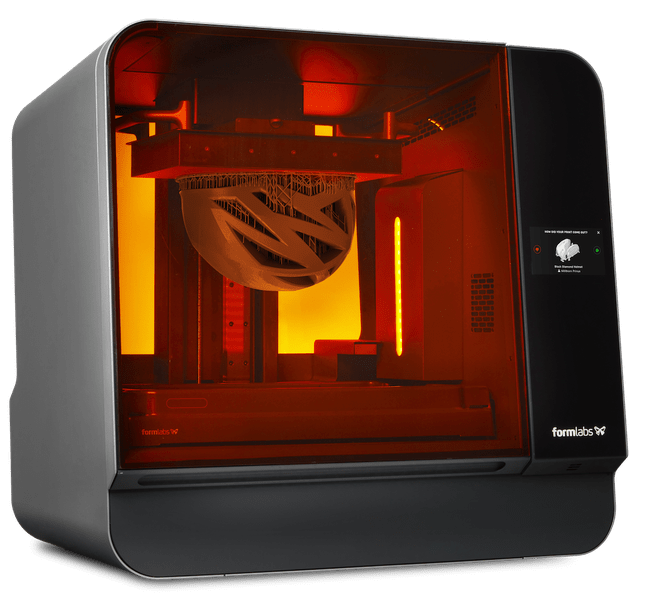

Formlab Form 3D Printer has become quite popular among the audience. It uses high-tech Low Force Stereolithography to form 3D objects with maximum preciseness. In this review blog of ours, we’re going to review this 3D printer in great detail.

Formlab Form 3D Printer – A General Overview:

The Formlab Form 3D Printer is a resin 3D printer that offers high-quality prints at an affordable price. It features a simple, user-friendly design that makes it easy to get started with 3D printing. The Form 3D Printer uses UV-curable resin, which is cured by exposure to UV light.

This resin 3D printer is available in a variety of colors, allowing you to create beautiful, realistic prints. The Form 3D Printer is ideal for creating jewelry, models, and prototypes. It’s also great for hobbyists and educators who want to get started with 3D printing.

SLA, or Stereolithography, is one of the most spectacular additive production processes. Instead of piling up films of plastic via extrusion, which is the process of how fused filament production works, SLA observes coatings of liquid-resin-treated solids with the laser.

After each coat is published, the publisher’s tank maneuvers to peel the freshly printed coat off the resin tank surface, and then the created platform bed is raised to permit another coat of resin to go under the built platform.

When perceived as a time-lapse, the process looks as if the 3D models are getting ‘pulled’ from the plate of liquid resin. It is all quite sci-fi and remarkable indeed.

Anyway, in terms of SLA, no one does a better job than Formlabs. The company’s first 3D publisher, Form 1, created ripples in the desktop three-dimensional publishing industry by launching stereolithography to a consumer base for fused filament fabrication.

Fast-forward to the year 2019, and the market has witnessed Form 1+, Form 1, and the mesmerizing Form 2 three-dimensional publisher come and go. What we have these days is the most premium 3D printer by Formlabs. This is known as Form 3, and it is somewhat of a unique breed to its forerunner. It is more accurate, powerful, and swifter.

Here is a comprehensive analysis of all the things you require to know about this 3D printer.

Technology

Form 3 is an SLA 3D publisher. However, the procedure has been improved to generate a fresh process known as Low Force SLA.

Low Force SLA addresses the largest engineering difficulty inverted SLA brings to a 3D desktop-size printer, i.e., the noticeable forces applied on aspects during printing. Those forces are so energetic that the structure of support can be challenging to remove.

The Form 2 variant does an excellent job of controlling those forces with calibration. Even though ultimately, intensifying peel forces impose limitations to the publishing process, such as repeatability and reliability.

With the launch of Low Force SLA, Form 3 dramatically reduces the energy exerted on aspects during the publishing process. LFS 3D printing utilizes linear illumination and a pliable resin tank to decrease print forces. This initiates the structure of light-touch support and elevates performance.

The lower forces decrease the strain on features and have a rather remarkable effect. They enable you to snap away from the structure of support easily. They can genuinely pull out from the support structure, and it will snap off properly. No fuss, no mess, thanks to the Low Force SLA and the smart engineers of Formlabs.

Inside Form 3, there is also a new optics engine with new LPU and mirrors. Formlabs initiated development on the new optics engine right after Form 2. So it has been a couple of years in development. The Light Processing Unit contains the mirrors and lenses system.

A galvanometer places a high-density laser ray in the direction of Y, which is then directed via that process to the publishing bed.

The outcome is a more precise and repeatable, three-dimensional publishing process than ever before!

Industrial-quality publishing

Form 3 is a massive upgrade from Form 2 in different ways. On top of its supreme Low Force SLA, it can publish four times faster. Form 3L has a build volume that is five times greater than Form 2.

Another aspect of improvement is publishing quality. Form 2 used to be one of the most premium 3D printers on the market for quality. But the Form 3 version is even more improved. It utilizes the parabolic mirror, which keeps a laser at the right angle to create a plane for uniform prints. And the laser goes through the spatial filter to ensure a proper laser spot so there is no edge corruption.

The closed-loop calibration utilizes optical sensors to frequently correct power and scale, creating an adjustable 3D printing process. This enables you to publish continuously without stopping Form 3 and modifying it.

The air-heated publishing chamber is something fresh for this Form 3 version. This temperature commanding system works with the self-heating resin tank in Form 2. The outcome of all this is that Form 3 generates industrial-quality prints, which can be done rapidly and at a large scale.

Specifications and build volume

Form 3 offers a 5.7 X 5.7 X 7.3 in or 14.5 X 14.5 X 18.5 cm build volume.

This machine is categorized as a ‘desktop three-dimensional printer,’ which can fit on the desk.

Form 3 Printer action at a glance:

- All the resin cartridges by Formlabs as material support.

- 25 to 300 microns layer resolution.

- 14.5 X 14.5 X 18.5 cm or 5.7 X 5.7 X 7.3 in build volume.

- Almost 14 cm touchscreen display user interface.

- Connectivity via Ethernet, Wi-Fi, and USB.

- Has the printing technology of Low Force Stereolithography or LFS.

- Arrives with the laser Technology of LPU or Light Processing Unit, which has 250 mW405 nm.

- XY Resolution of 25 microns.

- Automatic leveling of the build platform.

The Form 3L offers the same features as the above, apart from the build volume growing to 30 X 33.5 X 20 cm or 11.8 X 13.2 X 27.9. It also has two light processing compartments versus the 1 in the variant of Form 3.

Usability and interface

You can command Form 3L and Form 3 at source utilizing the almost 14 cm touchscreen display installed into both machines’ front parts. It is a responsive and snappy panel in the presence of a 1280 X 720 resolution. So you can not see the individual pixels, which is a good thing.

You can command their workflow via the homegrown software of Formlabs. It is called PreForm, and it is accessible for Macbook and PC. With PreForm, you can upload their unsliced OBJ or STL file, which will do the slicing for them in a 3D slicer. It is a clever application as it can automatically repair the broken meshes and pick out the suitable print settings according to what it observes.

The PreForm application can immediately set up the layout support and orientation of your printer without any human involvement. This enables a Form 3L and 3 to be utilized by anyone. It genuinely takes an instant to load the file, press publishing, and permit the publisher to do the work.

Of course, automatic controls are not always the most desirable option. The good news is that the PreForm application has strong manual controls, permitting you to command an array of parameters, such as size and support density. You can also carefully vary the thickness of the layer throughout publishing, something that can be indispensable for highly complicated aspects such as the ones in the presence of overhangs.

The PreForm application is a virtual software tool that you can use to command material terms and printers in a communal area from anywhere globally, with a strong internet connection.

With regards to build-up, it genuinely can not be easier. When you plug in Form 3 for the first time, it will guide you via the process through the touchscreen with an online unboxing experience. It undergoes each of the footsteps, such as installing the cartridge, in the presence of directions on how to do it.

What is in the package?

A Form 3 is accessible in 2 packages: the complete package and the Basic Package.

A Basic Package involves:

- Finishing Kit

- Form 3 three dimensional printer

- Form 3’s Resin Tank

- Build Platform

A Complete Package adds:

- 2-year subscription of Pro facility plan

- Form Cure

- Form Wash

- 1L of Standard Resin

A Complete Package will be a lot more costly, but it is worth it as you can assemble parts in-house.

Final thoughts

Formlab Form 3D Printer is one of the most useful 3D printers in the market. It’s equipped with useful features and advanced technology to help people print 3D models with accuracy. In the information given above, we have provided our review of the printer in detail. Make sure to read all its factors before you decide to buy it.